Blog

Hey everyone, it's Eric Christie with Boxer Inspections, checking in with another installment of "What did we see at the inspection today?". This one was definitely unique and quite an experience. I was called out to a new construction inspection, but this wasn't the typical buyer-hired inspection. The builder themselves actually asked me to come out and perform an inspection on the property. Why? Well, they, like all the other major builders, are offering a 10-year structural warranty. They wanted to ensure that their various tradespeople were doing their jobs correctly, minimizing the chances of costly problems down the line that could fall under that warranty. Essentially, they're trying to prevent improperly done workmanship from handing them a headache later. Part of our process on this particular inspection involved testing the plumbing and drainage systems. This was a two-story house, so I had gone upstairs and filled all the sinks, basins, and tubs with water. My goal was to simulate actual use and see how the drainage system handled the volume. I had just finished filling the master bathroom tub and started the process of draining it.

Hey everyone! I'm back with another video of What Did I See At The Inspection Today?? You know, I've been working as a home inspector in Sugar Land TX for a while now, and I honestly think I've seen a lot of interesting things. But today, I’m performing a home inspections in Missouri City TX. Unique features can be found in any home regardless of the location – Sugar Land Tx, Richmond TX, Rosenberg TX, or like today, in Missouri Cit TX. I often stumble upon the unexpected. Today was definitely one of those days! I performing the inspection in the garage, normal giant 4 car garage. HA! It seemed like a pretty standard garage at first glance. But then, my eyes landed on something on the wall that made me pause. It was a controller. Now, this wasn't just any light switch or garage door opener button. It looked like a lift mechanism controller usually seen in industrial applications. Places where you need to control a crane from the ground. Seeing this kind of control in a residential garage was, to say the least, unique. It was the first for me; I had not seen this before. Naturally, I had to figure out what this was all about! I followed where the cables or tracks seemed to lead, and that's when I discovered the really cool feature of this house. This property has a lift that allows you to put items in the attic. How neat is that? Attic storage is common in homes, but getting things up there, especially heavy or bulky items, is often a hassle and can be dangerous. This system provides a mechanical assist. The setup involves a platform, cables and a winch in the attic. From what I saw, the platform goes a bit lower than seen in the video – presumably lower to the ground level of the garage, making it easier to load things onto it. Once items are loaded onto the platform, that's where the wall-mounted controller comes into play. Using that control, you can just lift them up to the attic. After the lift has done its job and brought your stuff up, you can then climb the ladder to attic and once you're up there, you can easily unload, put it where you want to. The primary benefit of this unique system is crystal clear: you do not have to struggle with trying to get heavy boxes or heavy containers up the stairs. Anyone who's ever tried to haul a heavy storage bin or a piece of furniture up a ladder or a flight of narrow attic stairs knows exactly how difficult and even risky that can be. Reducing the need to manually carry heavy loads while navigating attic stairs significantly decreases the potential for slips, falls, or muscle strains. It’s designed to help people manage their attic storage much more easily and safely. Overall, finding this system during the inspection was simply a neat feature. It's pretty cool. It really highlights the kind of inventive solutions you sometimes find in homes that make daily life easier and safer. It's these kinds of unique discoveries that make being a home inspector in Sugar Land TX (or wherever the inspection takes me!) constantly interesting. Hope you enjoyed hearing about this unique find! Have a great day, everyone

When you're looking at buying a house, especially one that's been recently renovated, you expect everything to be updated and in perfect working order. A home inspector plays a crucial role in verifying this, meticulously checking components that might look fine on the surface. Sometimes, though, standard visual checks aren't enough, and that's where technology comes in. Eric Christie from Boxer Inspections , a name familiar to those seeking home inspections in Missouri City Tx , recently shared a great example of this from a property inspection there. The property was a renovated house located in Missouri City . The kitchen was particularly nice, boasting lots of new appliances . Everything looked aesthetically pleasing . However, the environment created a specific challenge for inspecting the gas cooktop: there was a lot of light coming in . Eric noted that because of the bright conditions, it was difficult to visually tell whether the burners were on . The flames, while present, were not easily discernible against the bright background. In such a situation, an inspector might traditionally consider using a temperature probe to confirm if the burners were heating up. This is a valid method, but on this day, Eric opted for a different tool from his kit: his thermal camera . This choice offered a different perspective and proved to be quite insightful. Bringing out the thermal camera , Eric found he could zoom in , which he described as "kind of neat" . The thermal camera's strength here was its ability to detect and visualize heat. Through the thermal lens, he could actually see the flames and the heat rising off the burners . Getting a bit closer provided an even clearer view of this heat signature. This demonstrated functionality in a way that the naked eye simply couldn't perceive in the bright light conditions. This use of thermal imaging wasn't just interesting; it served a practical purpose for the inspection process, which is key for any thorough home inspector [implied]. Being able to visualize the heat patterns allowed Eric to take a quick picture . This thermal image provided a clear record , serving as confirmation that all of the burners were functioning and that they were heating up , which is, as he noted, "good" . It offered concrete documentation of the appliance's operational status that was difficult to get through a simple visual check. Eric highlighted this experience as an "interesting factoid" and an illustration of the "different ways of doing inspections" that inspectors encounter depending on the specific property and its conditions . It emphasizes the importance of adaptability and using the right tools – like a thermal camera – to ensure a comprehensive and accurate assessment, especially in situations where standard methods are hindered. For those seeking home inspections in Missouri City Tx , this demonstrates the depth of the inspection process. This application of thermal technology is a smart workaround for a real-world problem encountered during a home inspection [implied], ensuring that crucial details about the property's components are verified and documented. It's a testament to how skilled home inspectors , including those performing home inspections in Missouri City Tx , leverage specialized equipment to provide thorough reports to their clients. Keep in mind, not all inspectors have specialized equipment to use for home inspections. So, choose your home inspector wisely. I serve many cities around Missouri City, including Sugar Land, Richmond, Rosenberg, Stafford, Bellaire, Alief, Meadows Place, Katy, & Fulshear. Call me to schedule at 281-783-3030 Eric Christie of Boxer Inspections shared this glimpse into his process, wishing everyone a great day.

Pre-pour foundation inspections are crucial for ensuring structural integrity and compliance with engineering plans and building codes by allowing inspectors to verify key elements before the concrete is poured and potentially conceals defects. One of the fundamental aspects of these inspections is the verification against the engineering drawings. I emphasizes that having the drawings on-site is essential to determine if the collected dimensions are correct. Without these drawings, I am merely collecting measurements without context. In this specific inspection, the builder provided the drawings, although they were in poor condition. The inspection involves checking the dimensions of various structural components. For instance, I examine the beams, which run across the house and along the perimeter in both directions, creating pad sections. I specifically check the depth and width of these beams at the bottom. In this case, the drawing specified a bottom width of 10 inches, which the inspector verified, but noted that 12 inches is more typical. The inspector also measures the width at the top of the beam where two pads come together. Additionally, the height of the post-tension cables (tendons) from the bottom of the beam is checked. The spacing of these cables is also noted, which is usually around 2 to 2.5 inches in this case where two cables are present in a beam. To ensure the overall layout conforms to the plans, I use a 100-foot tape measure to determine the length and width of the property/house and to confirm that everything is squared up. Measurements are taken at three points to identify any variations in the forms. Furthermore, the location of each tendon and beam is measured from a reference point (the front of the house in this case) and compared to the specifications on the drawing provided by the structural engineer. The consistency of the beam depth around the entire perimeter of the house is also verified. Compliance with building codes is also addressed during these inspections including the National Electrical Code (NEC). I discuss a concrete encased electrode used for grounding. I reference the National Electrical Code's requirement of 25 ohms of resistance between the ground plane in the main panel and earth ground. The NEC states that if this resistance cannot be achieved, a second grounding rod must be installed which would include a concrete encased electrode in the concrete. However, there is an exception in the code regarding vapor barriers placed between the soil and concrete, which, according to the NEC, prevents the electrode from being in direct contact with the soil. I consistently write this up at inspections, but electricians and builders often disagree with their interpretation. The presence and proper installation of a vapor barrier is also checked for compliance and structural integrity. I check to ensure it is taped and sealed to prevent groundwater from seeping into the foundation. I identified the use of an unapproved tape (Kingspan) for sealing, as the manufacturer's recommendations states it should not be used in contact with moisture. While duct tape was also used and not explicitly prohibited by its manufacturers, I feel it not the best tape for this purpose. Finally, I also look for issues that could compromise the foundation's integrity, such as trash within the forms that needs be removed before the pour. I also note the importance of proper drainage, observing a drainage channel was present at the front of the home but suspect the beams were not adequately sloped to direct water towards it. I observed the straightness of the beams, which is important for the structural integrity of the home. In summary, pre-pour foundation inspections ensure structural integrity and compliance by meticulously comparing the constructed forms and incorporated elements against the engineering drawings and relevant building codes. This includes verifying dimensions, the placement of structural components like beams and tendons, the proper installation of vapor barriers, ensuring adequate drainage provisions, and identifying any potential issues like debris that could negatively impact the foundation's integrity. For greater details on this inspection, please watch the YouTube video or you can listen to the PodCast. By Eric Christie, Boxer Inspections LLC

When it comes to home inspections, the roof is one of the most critical areas to evaluate. A thorough roof inspection can reveal potential issues that, if left unresolved, might lead to costly repairs or damage to other parts of the home. Here’s an in-depth look at some of the issues home inspectors typically assess during a roof inspection and some tips for addressing common problems.

Water heaters are crucial to every home, but they are prone to problems that disrupt daily life and can lead to costly repairs. A Professional Home Inspector at Boxer Inspections LLC, often encounter these issues during their home inspections. Below are the top five water heater issues and how they’re addressed, incorporating insights from professional home inspections.

A home inspection before winter is crucial for multiple reasons. Preparing your home for the cold and potentially harsh conditions of winter can help you avoid costly repairs and ensure the safety and comfort of your family. Here are some key reasons why a home inspection before winter is important and should be part of a yearly consideration: Identify and Address Potential Issues: All homes need maintenance over time, just like cars and just like humans! A thorough home inspection can uncover any existing or potential issues that could worsen during the winter months. This may include issues with the roof, insulation, heating systems, plumbing, and electrical systems. Identifying problems early allows you to address them before they become major headaches.

Recently, during a new construction inspection, Boxer Inspections encountered and reported as deficient a contaminated dishwasher. In this case, the dishwasher had dark spots on both the upper and lower dish racks. It was concluded the most likely cause was fungal growth. No samples were sent to a lab for analysis to verify. Therefore, there was not any confirmation as to what it was. I believe that even if samples were taken and sent to a lab, the result would have been the same – Replace the Dishwasher! The Professional Home Inspector at Boxer Inspections is going to look for items like this. How many times have you toured a home and looked inside the dishwasher? Well, you might now, after seeing this, right?!

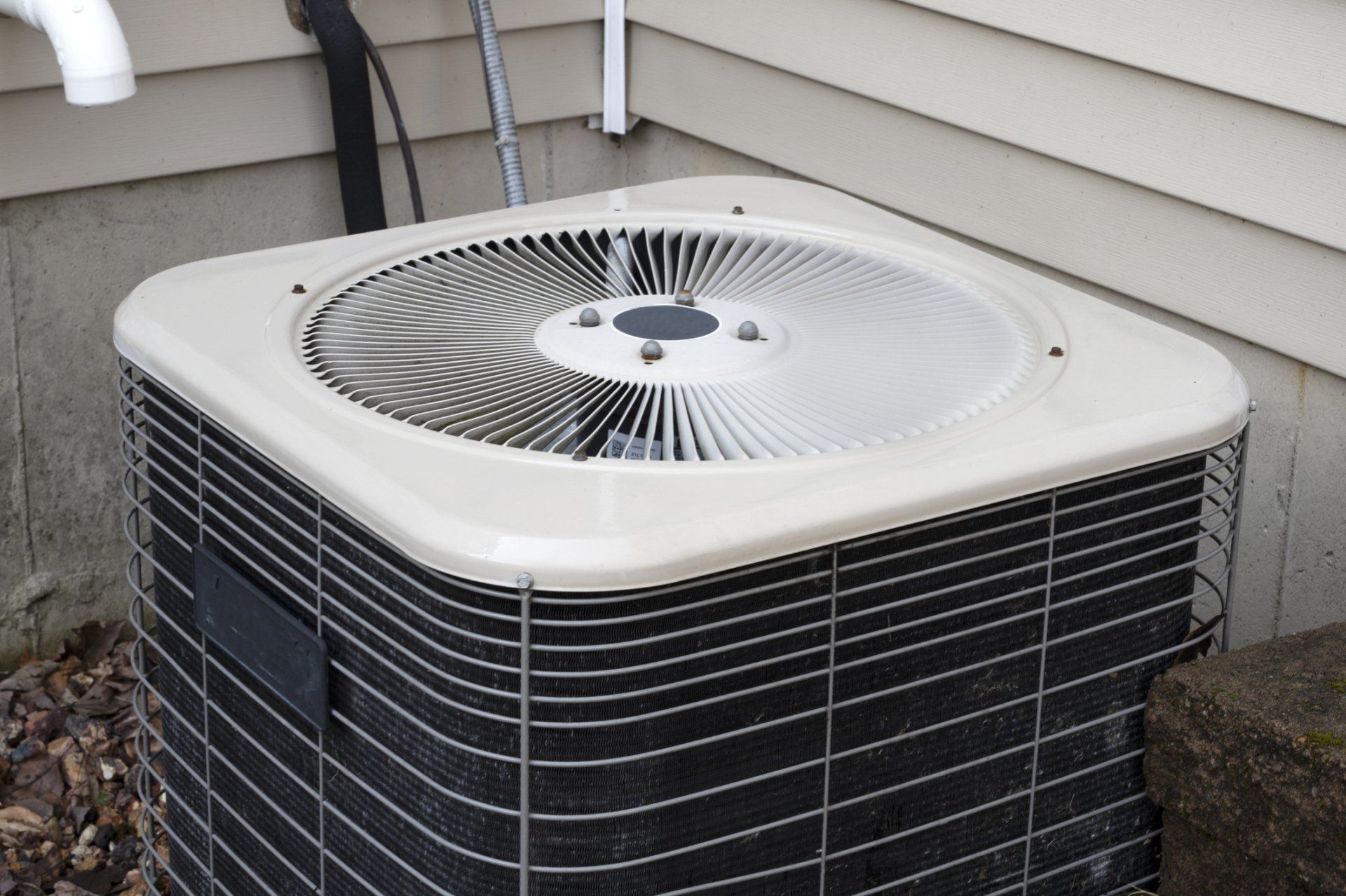

Decades ago, the electrical system in homes used fuses to protect the electrical circuits and equipment from and electrical short or overload. An electrical short or overload occurs when there is a direct pathway to ground in an electrical circuit. When this occurs, large amounts of electrical current will flow in the circuit including the wiring, connections, and the electrical fixture. High current flow causes heat to increase in the circuit. Wires, switches, outlets, connections, etc will heat up. When these components pass high current, they will also begin to heat up. As they heat up, resistance in the wire or component increases. The resistance limits the amount of current that can flow. The result of all this behavior is that current will reduce as the resistance increases, but the heat generated will increase. When components get hot enough, they can ignite combustible material nearby. Due to this, an electrical short can cause a fire or can electrocute someone. To protect electrical circuits a device needs to be installed between the electrical source and what is known as the load. The load is the electrical device, switch, outlet, wiring, etc. The device limits the amount of current that can flow. These devices will fail or open the circuit to stop the current flow. In modern homes, circuit breakers are used to protect equipment and components. When the current passing through a circuit breaker exceeds a specified value, the circuit breaker will trip. This action opens the circuit, stops the flow of current, and helps to protect occupants and the home. In older homes, the electrical protection devices used were fuses or fusible links. These types of protection devices will melt an internal wire which creates an open circuit. The open circuit stops the flow of current thus protecting the circuit. The home shown in the video has the outside AC condenser with the fuses replaced with copper tubing. This removed the protection from the circuit. In this particular case, the main electrical panel had been updated with a newer panel at some point in the past. The protection for electrical circuits changes from fuses to breakers in the panel. The correct update would have been to removed the old fuse protection AC disconnect and install a modern disconnect that has a removable plate. This removable plate will disconnect electrical power from the outside AC unit to allow service personnel to work on the unit. During inspections, unusual installations like this are often found . When dealing with electrical items and electrical equipment, doing it safely should always be the #1 consideration. However, the requirement or need to reduce the costs for the work, often forces corners to be cut In this video, I looked in the AC condenser disconnect and the fuses had been replaced by copper pipe. This is very dangerous if there is not current protection in the main electrical panel. If the fuse is smaller than required by the condenser manufacturer, you can get nuisance trips where the start up current burns the fuse. Techs would put these pipes in to prevent the fuse from burning through. Very dangerous. On the bright side here, a correctly sized breaker was installed in the main panel protecting the condenser. #boxerinspections #residentialhomeinspection #electricalsafety

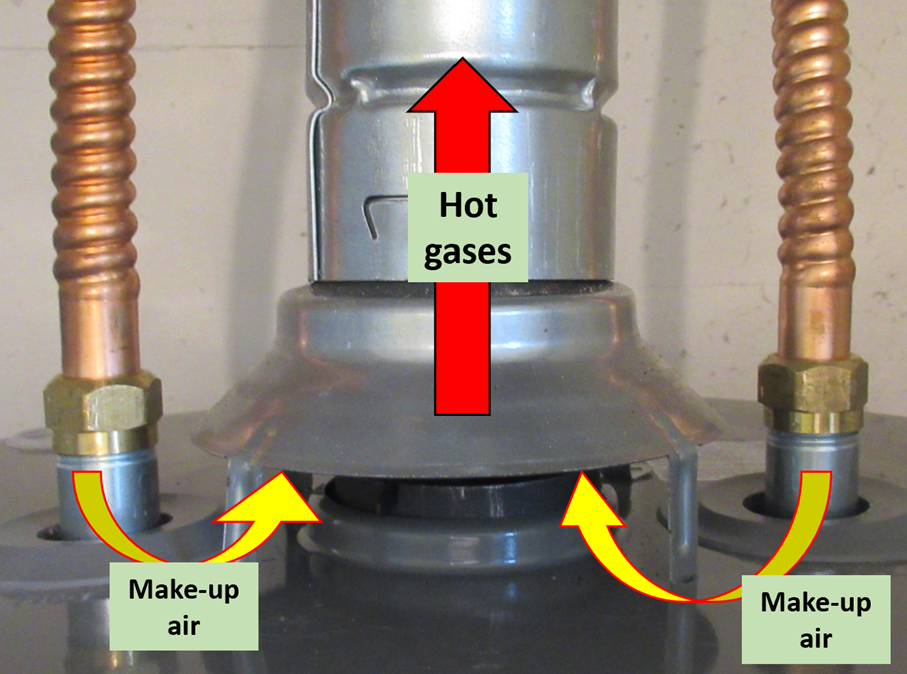

In video provided at the bottom of this article, I was inspecting a 90+ years old. The home was equipped with gas appliances including a gas water heater. Any time there are gas appliances in the home, it is vital a carbon monoxide detector (CO) be installed in the home and that the appliances be regularly inspected for proper operation. The location for the CO detector should be near the gas appliances. Ideally, that would be near the kitchen with a gas stove and attic for a gas water heater or gas furnace.